Home / Applications

Solar Concentrator for Solar Enhanced Oil Recovery

What is Solar Enhanced Oil Recovery?

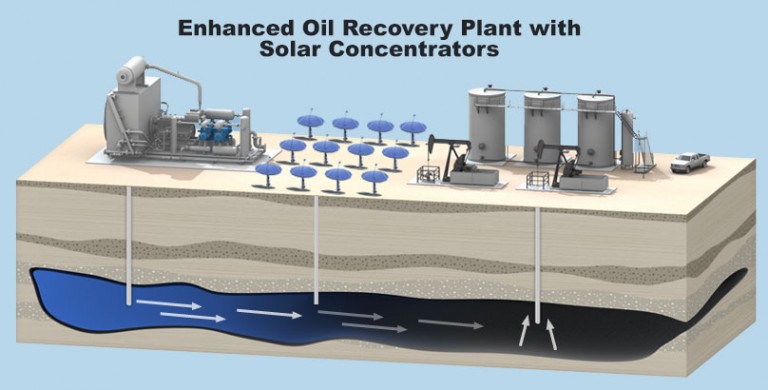

Solar Enhanced Oil Recovery (Solar EOR) applies thermal recovery using concentrated solar power. Large solar concentrators focus the sun’s energy to produce high temperatures, which are used to heat water and generate industrial-grade steam.

This steam is injected directly into the oil reservoir, where it heats the heavy crude oil and reduces its viscosity. As the oil becomes thinner and more mobile, it can flow more easily through the rock formation and be pumped to the surface.

Traditionally, this steam has been produced by burning natural gas in boilers, making EOR one of the most energy-intensive and fuel-consuming operations in oil production. Solar EOR replaces a major portion of that fuel use by using the sun as the thermal source.

In strong solar regions, Solar EOR can supply up to 80% of a field’s annual steam requirements. Solar-generated steam is injected during daylight hours, while smaller amounts of gas-fired steam are used at night or during low-sun conditions to maintain continuous reservoir heating.

By using solar concentrators to generate steam, operators can displace large volumes of natural gas consumption without reducing oil output. The result is the same recovery performance with lower operating costs, reduced emissions, and a more sustainable approach to heavy oil production.

In essence, Solar Enhanced Oil Recovery delivers the proven effectiveness of steam-based EOR, but replaces fossil fuel heat with clean, concentrated solar thermal energy.

Solar Concentrator Technology For Enhanced Oil Recovery Plants

When equipped with the Evacuated Absorber Module, the 9M Solar Concentrator is capable of producing steam at temperatures of up to 400°C, matching the thermal output typically generated by natural gas-fired systems used in Enhanced Oil Recovery (EOR).

Unlike enclosed solar thermal systems, the 9M Solar Concentrator does not require installation inside a greenhouse or glass enclosure. Its open-structure design allows for flexible outdoor deployment, including installation on sloped or uneven terrain. This eliminates building constraints and enables scalable expansion directly within or adjacent to existing oil field infrastructure.

The system integrates seamlessly with conventional EOR operations. During daylight hours, the solar concentrator delivers high-temperature thermal energy to generate steam for reservoir injection. At night or during low-sun conditions, the conventional steam boiler or gas-fired system automatically resumes operation, ensuring continuous 24-hour, 7-days-a-week steam supply without interruption to oil production.

This hybrid configuration allows operators to significantly reduce natural gas consumption during daytime operations while maintaining consistent recovery performance and operational reliability.

Touchless Mirror Cleaning System

In regions that experience sand storms or dust, the solar concentrator can be equipped with a robotic cleaning system that uses a “touch-less” high pressure water to clean the mirror surface without coming into contact with the reflective mirror.

With the robotic touch-less mirror cleaning system, the solar concentrator can maintain a high solar enhanced oil recovery production by providing maximum reflective energy to the Evacuated Absorber Module.

Benefits of Using 9M Solar Concentrator for Solar Enhanced Oil Recovery

Lower Levelized Cost of Energy (LCoE)

Designed for high thermal efficiency and reduced civil infrastructure requirements, the 9M Solar Concentrator helps lower the overall cost of steam generation compared to conventional solar thermal systems.

Dual-Axis Solar Tracking

Unlike single-axis parabolic trough systems, the 9M utilizes dual-axis tracking to maintain optimal sun alignment throughout the day and across seasons, maximizing solar capture and increasing overall energy yield.

High-Temperature Steam up to 400°C

Capable of delivering industrial-grade steam equivalent to natural gas-fired systems, making it fully compatible with Enhanced Oil Recovery operations and other high-heat industrial applications.

Touchless Robotic Mirror Cleaning

Equipped with an automated high-pressure cleaning system that removes dust and debris without physical contact, preserving mirror integrity and maintaining peak reflectivity in harsh environments.

No Glasshouse Enclosure Required

The open-air design eliminates the need for enclosed greenhouse structures, reducing construction costs and enabling flexible outdoor deployment.

Deployable on Uneven Terrain

Modular and adaptable, the system can be installed on sloped or irregular land, expanding site options and simplifying large-scale deployment.

Highly Reliable and Simple to Operate

Engineered for industrial environments with straightforward mechanical systems and automated controls, ensuring consistent performance and high operational uptime.